Innovation

Complete site conditions integration

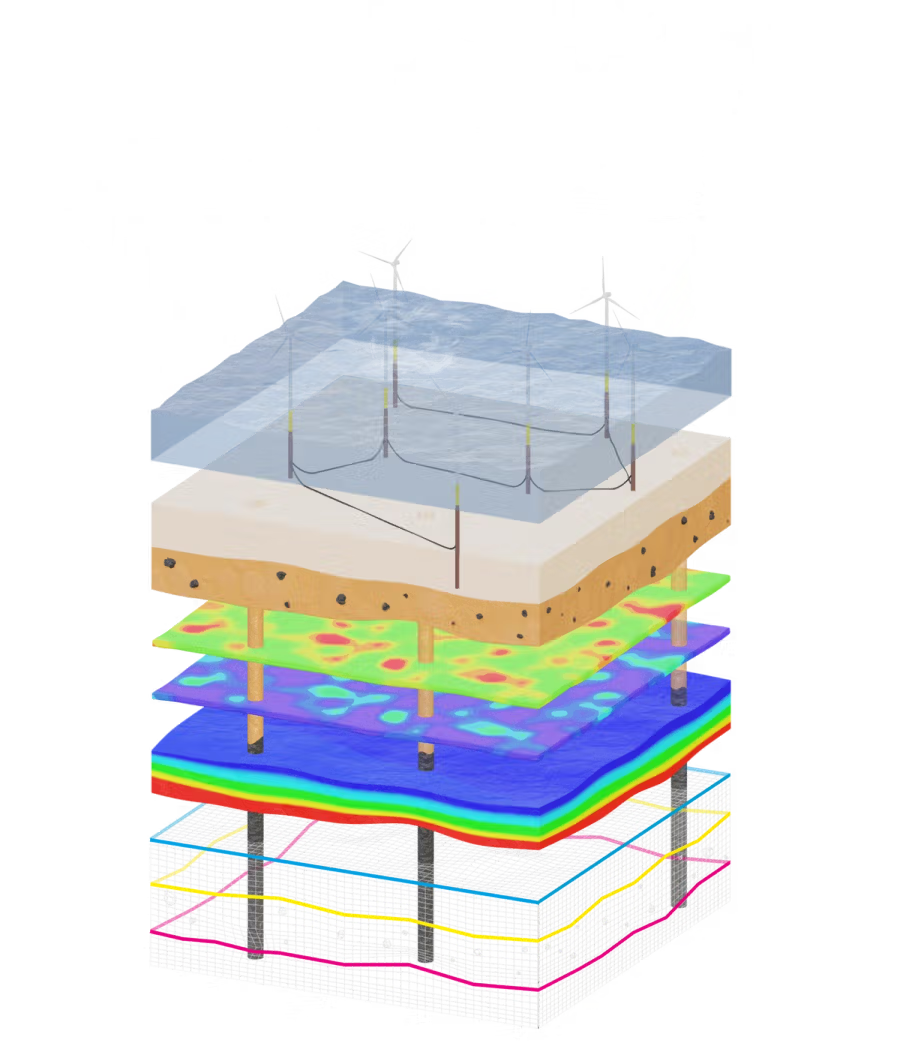

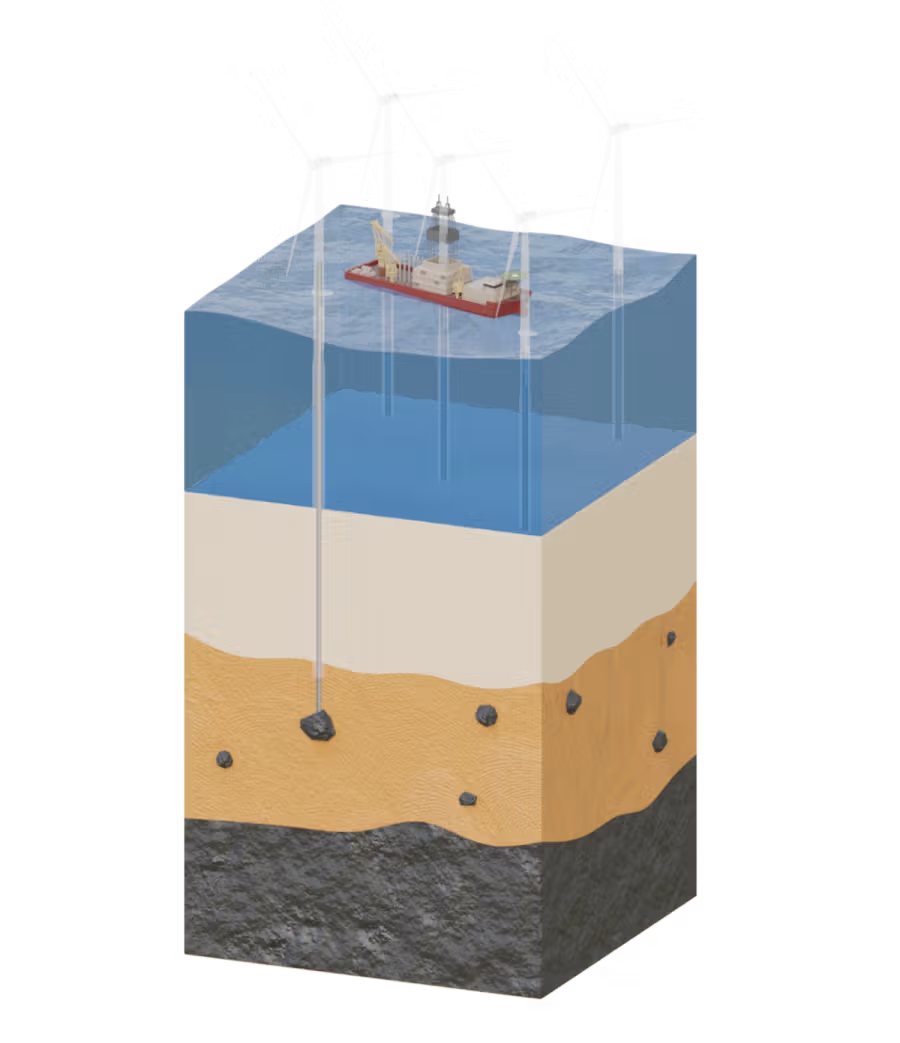

The atmospheric and oceanographic site conditions across a wind farm site interact with one-another to define the loading on the support structure foundation, both via the wind turbine and directly on the support structure itself. The geotechnical site conditions then define the response of the support structure, the dynamic characteristics of which feed back to further influence the loading. Hence the overall successful design of an offshore wind farm must not only capture the individual site conditions, but also their complex and collective interaction.

The challenge is further compounded by the governing site conditions being spatially variable across a site, or in some cases variable over the design lifetime, for example, seabed levels in environments subject to sediment mobility. This brings a further challenge of needing to generalise, or cluster, site conditions appropriately and sufficiently to enable practical design, but whilst retaining sufficient resolution to deliver a design which is optimised for each individual location.

Wood Thilsted’s approach to addressing this challenge and the underlying site conditions integration is founded on deep, discipline-specific understanding of the many different site conditions, and also their interaction. This is captured in our workflow using innovative software twinned with collaborative, inter-disciplinary working practices.

"Our software-driven workflow starts with building blocks which enable expert derivation and characterisation of the different site conditions, for example, clustering algorithms for metocean design load cases, or routines to derive and calibrate site-specific geotechnical correlations. It then combines these conditions in engineering routines which model their interaction and optimise the overall design. "

Bruna de Queiroz

Lead Scientist (Metocean), Climate Analytics and Loads

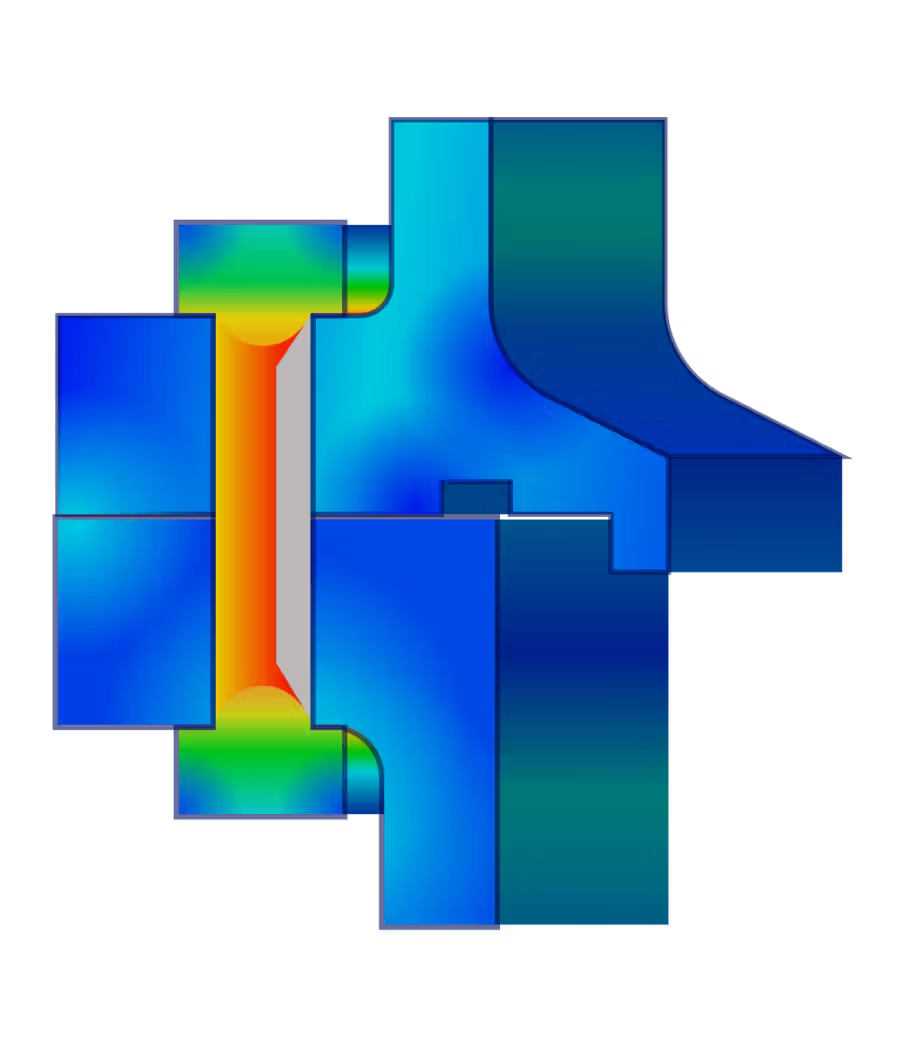

Pile soil analysis

Our 3D FE analyses of the soil structure interaction is fully integrated and controlled by our in-house monopile design software (Morpheus) to ensure consistency between data assumed for foundation design derivation and the 3D FE model. We have undertaken an extensive FE benchmark test toward the PISA pile load tests in Cowden and Dunkirk to prove accuracy and integrity of the models we use, to ensure that the simulations provide trustworthy and accurate results. Our models are calibrated solely to soil test data without application of post-fitting parameters. Therefore, when properly calibrated, our 3D FE models are highly reliable and capable of evaluating the impact of changing modelling conditions, such as changes of pile diameter, soil layering and parameters, etc.

The calibration of the constitutive models follow an innovative approach where the calibration parameters are automatically calibrated against relevant high-quality laboratory data using the least mean square method to find the most optimum fit to each individual test. This implies that up to hundreds of simulations are performed for each test leading to optimised calibration parameters for each governing geotechnical unit.

"Once the constitutive model is calibrated, soil reaction curves covering the geometrical space of the foundation designs are extracted from the 3D model to be applied in a simpler finite element model. The simpler finite element model is less computationally demanding when deriving hundreds of offshore foundation designs and therefore allows for a greater degree of structural optimisation, leading to highly optimised position, specific foundation designs accounting for fabrication and installation constraints. "

Brian Mackenzie

Technical Director, Geotechnical Engineering & Design

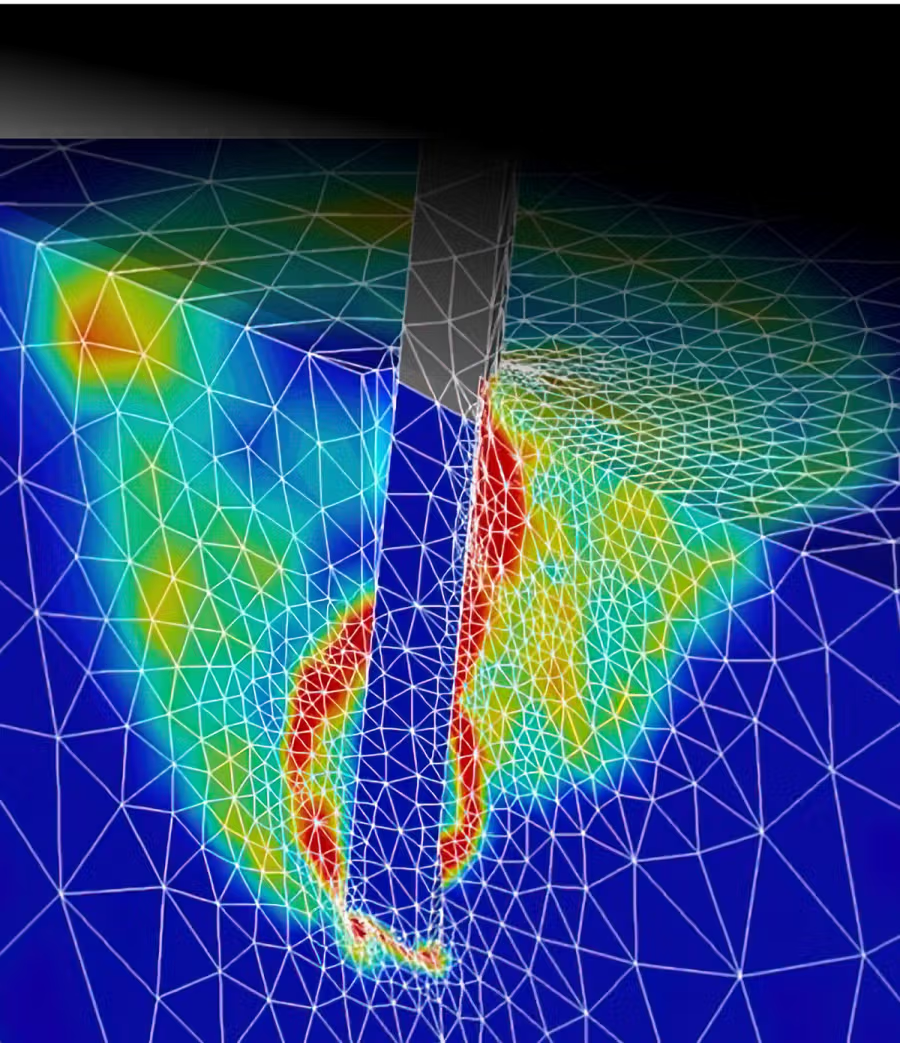

Cyclic degradation

Wood Thilsted has developed a novel cyclic degradation methodology for assessing the effects of cyclic loading arising from wave and wind actions on offshore foundations. For laterally loaded foundations this method is calibrated and benchmarked against the PISA cyclic pile load tests and is considered to reflect a rather high degree of accuracy given the uncertainties and complexity of modelling this problem statement.

Cyclic loading can lead to considerable strength degradation and cyclic mobility which affects the effective geotechnical properties of the soil volume supporting the foundation. This can result in excessive deformations, collapse and/or fatigue damage reducing the design life or the operational constraints of the structure if not carefully accounted for. Thus, accurate modelling of cyclic effects is vital to achieve an optimised and safe design. Applying soil reaction curves derived through 3D FEA modelling requires a efficient cyclic framework in order to be applicable for substructure and foundation design derivation as these reactions offer a more accurate and less conservative prediction of design stiffness and capacity. Therefore, capturing effects of cyclic loads is of high importance.

"The method is implemented in Wood Thilsted’s structural optimisation algorithm allowing for complex cyclic degradation analyses for each foundation design without compromising the computational costs leading to a fast turnaround in case there are any project risks that needs to be accommodated due to last minute project changes. "

Amir Shajarati

Technical Director, Geotechnical Engineering & Design

Seismic and liquefaction

"The free-field displacements are applied to the monopile through the linear (or non-linear) soil springs representing the soil-structure interaction at each soil layer with a sufficiently fine discretization. The response of the integrated structure is calculated via direct time integration, hence nonlinearities e.g. due to soil-structure interaction for large displacements or liquefaction can be accounted for. "

Evangelia (Evita) Skiada

Lead Engineer, Geotechnical Engineering & Design

Holistic engineering process

In our holistic approach to engineering, we consider design as an interconnected whole in which we seek to integrate the software efficiency with skills of designers from multiple disciplines into a collaborative effort for the good of the project. Using our efficient design software we eliminate most manual design processes whereby our engineers can devote their efforts to search for value-adding levers to improve designs by use of brute power to undertake millions and millions of design simulations. The results provide our engineers with a valuable holistic cross-discipline understanding of underlying design drivers, and it enables them to challenge any assumption, constraint, design method or design choice which is preventing a fully cost-optimised design to be achieved.

While reaching an acceptable design in a pre-defined step-by-step serial design process is straight forward and can be achieved with a relatively small engineering effort, the path to achieving a high-quality optimised design is only possible by numerous design loops including multiple design re-assessments, sensitivity studies, re-designs, repeated 3D FE calculations, re-clustering etc.

"The key to an efficient iterative design process is our multi-disciplinary engineers and a fully streamlined automated dataflow from early site assessment output to detailed analysis results. "

Christian Thilsted

CTO and Co-Founder,

Online reporting system (Dashboard)

"Our Clients have found the use of the dashboard really helpful in understanding the design development, and very engaging compared to conventional written reporting, which can stretch to many pages."

Martin Nielsen

Director and Head of Technical Delivery,

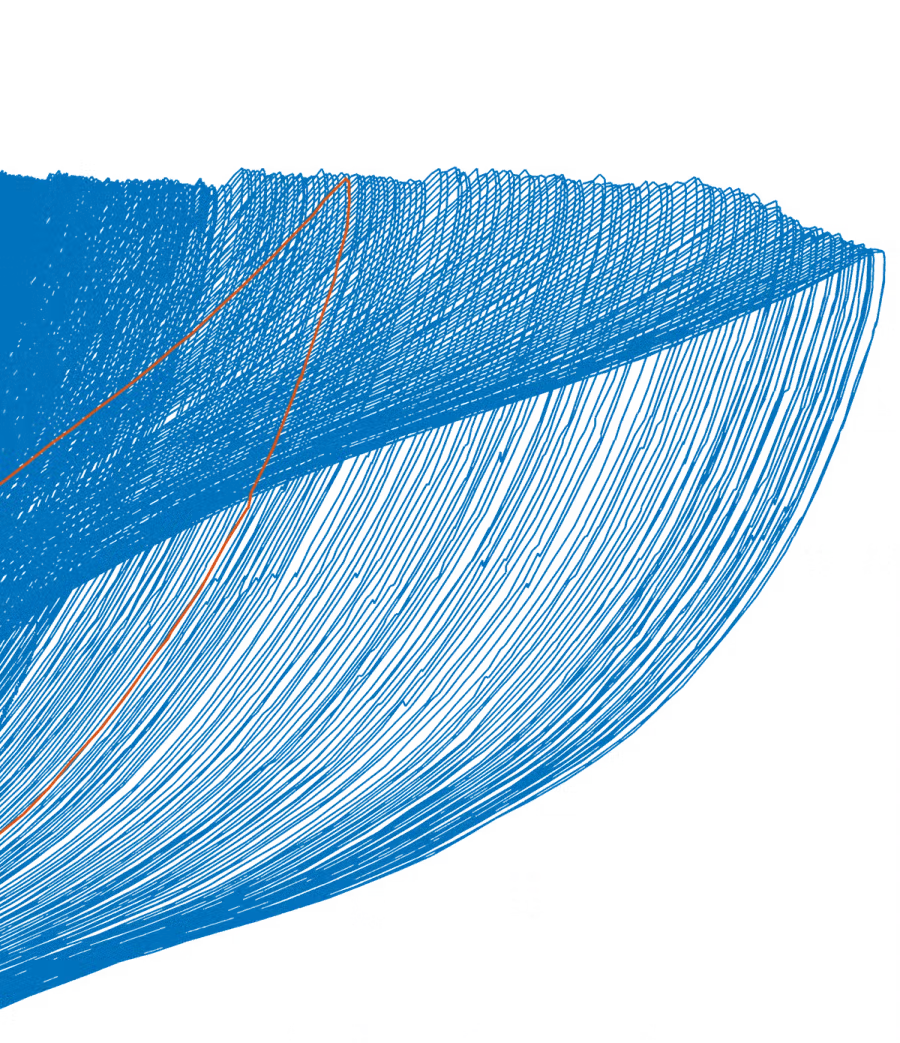

Geometry optimisation and sensitivity studies

"Our clustering approach, can besides standard measures as water depth and frequency/stiffness, also account for variations in tower, metocean conditions and geotechnical properties. And using our efficient and automated optimization tools for design and load assessment allows for direct assessment of the effects and potential improvements obtained by various clustering strategies. "

Dennis Hindhede

Director and Chief Consultant, Climate Analytics and Loads

Transport & Installation innovations

"Furthermore, At WT, our skilled team can offer route specific transportation conditions assessments and detailed fatigue analysis by spectral methods ensuring a safe transition from design, through fabrication to operational phase. "

William Hancock

Associate Director, Head of Secondary Structures, Secondary Structures

Connection design